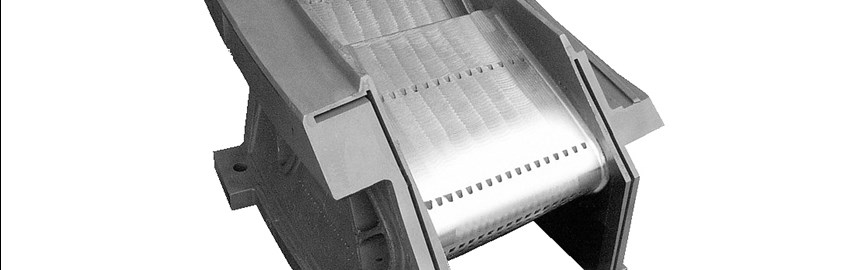

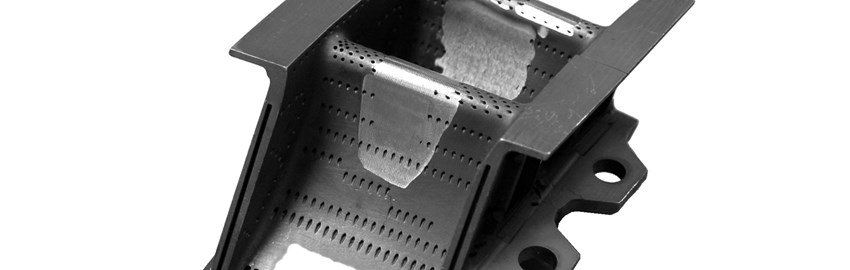

Nozzle Guide Vanes

Adaptive Machining

Are you looking for an integrated repair solution to enable you to quickly identify the location of each weld or braze patch on a component?

Our solutions for nozzle guide vanes are unique and take measurement data from gas-path surfaces to automatically make decisions about where to machine inner and outer location features.

Using a CNC machine connected to different types of high resolution metrology devices, we scan complete gas-path surfaces quickly to generate a data set of points to be processed and analysed by our Adaptive Machining technology, resulting in the generation of 5-axis machining paths which are unique to each individual component.

Our software is intelligent enough to remove rogue input data and identify unwanted braze material from the entire gas path to leave a part with high surface finish, meeting individual geometry and wall thickness requirements.

We remove cost and time from the repair process to enhance quality and consistency with the use of adaptive machining solutions for nozzle guide vanes.