Adaptive Machining

Lower cycle times, increase accuracy, and minimise operating costs by utilising Adaptive Machining for manufacturing new parts and for the repair of complex components

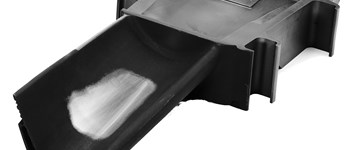

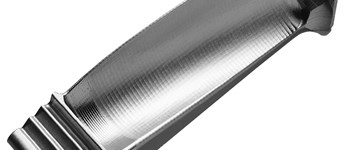

When coupled with standard CNC machine tools, our Adaptive Machining software provides the capability to machine and blend complex three-dimensional components and features automatically, where geometrical differences exist between one component and the next. It’s a powerful application for manufacturing castings and forgings that have inherent variation, parts subject to shrinkage variations from temperature fluctuations, die wear and heat distortion, or wear and tear during operation.

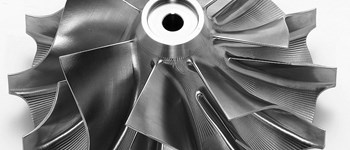

For freeform shapes with complex geometries such as gas turbine components, blades and vanes, our application-specific solutions eliminate human error and boost accuracy for new parts or those in need of repair.

See for yourself the powerful manufacturing capabilities of our unique approach to Adaptive Machining, by reading about our unique demonstration on an egg or watch the video here.