Adaptive Machining in an Egg Shell

| 30th March 2016

TTL's adaptive machining technology explained

Many of TTL’s customers or those who have attended our seminars will be aware of an interesting demonstration that we use to help illustrate our Adaptive Machining Technology by CNC engraving an eggshell via a fully automated process.

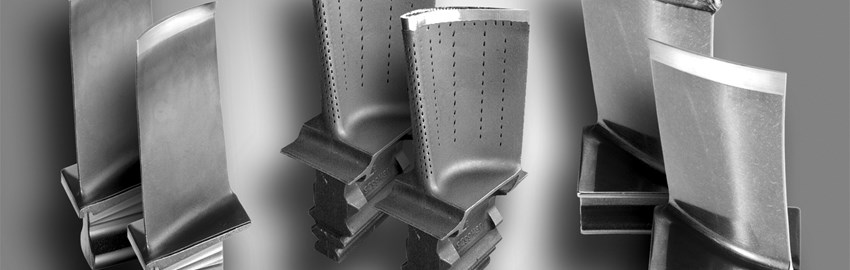

It’s true that using a 5-axis machine tool to engrave chicken eggs is rather unusual. However, this seemingly strange idea may not be as crazy as it first appears. Eggs do have some similarities with blades, vanes and components found in turbine applications; they are complex three dimensional shapes, difficult to fixture, easily damaged during the machining process and critically, no two eggs are identical.

We revised this demonstration to show the principles of Adaptive Machining and to illustrate the capability of our solutions. A company name or logo can be CNC machined into the shell of a raw egg using a standard 5-axis machine tool, without causing the shell to crack. Since eggs are all different in shape and size, each one is digitised and the resulting data captured via TTL’s Adaptive Machining Software where it is processed and a unique tool path for that particular egg is generated. The resulting NC programme controls a 5-axis machine tool, cutting to a consistent depth of around 0.05mm (0.002 inches), regardless of the surface variations.

The problems encountered when engraving the egg are technically similar to those of machining many features of new cast or forged blades or vanes, or removing the coating or blending excess weld from repaired ones.

For more details, contact us here.