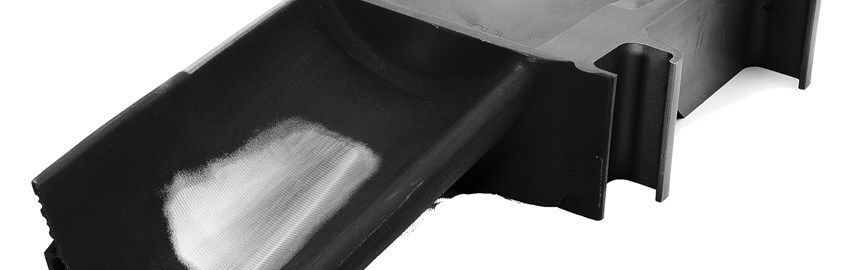

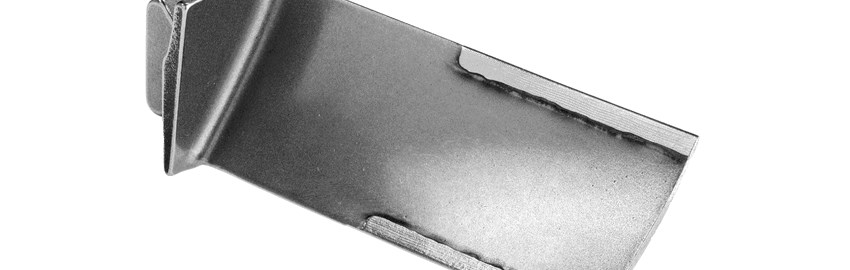

Fan Blades, Compressor & Turbine Aerofoils

Adaptive Machining

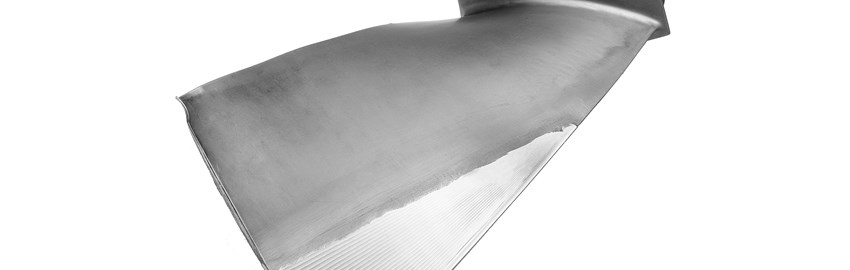

Fan, compressor, and turbine blades can be very difficult and expensive to manufacture and repair. The geometry of the aerofoils, chord width and Leading Edge profiles all contribute to the overall efficiency of an engine so accuracy in the repair process is essential and difficult to achieve with manual repair methods.

By using Adaptive Machining to repair these components, you can reduce cycle times, remove human error, achieve a virtually nett finish and benefit from a fast return on investment in capital equipment used for the repair of any type of fan, compressor and turbine blade.

Our Adaptive Machining technology is supported by custom designed fixtures that locate and hold difficult components optimally for machining. It takes control of the CNC machine to give precise control of all relevant parameters and can be used to repair parts from both hot and cold sections of the engine.

For fast and efficient definition and machining of Leading Edge problems and a faster, more accurate process, ask us about Adaptive Machining for aerofoils today.