Robotics Programming

Siemens NX | NX CAM

Plan, Validate and Optimise Machining Processes Driven by Robots

For a variety of manufacturing industries the use of robot machines is expanding rapidly. The demands on production require intelligent processes through robotic programming software to ensure consistent and accurate output. Two trends that are driving this change: recent improvements in accuracy, repeatability and payload capacity make robots adequate for increasing the number of machining tasks, and it is harder to find qualified workers that are willing to perform repetitive actions in tough environmental and physical conditions for a long time. With the use of robot machinery manufactures have the ability to achieve a sustainable production environment and consistent product. The Siemens NX CAM Software has proven to perform in demanding manufacturing environments

Beyond the familiar tasks of lifting, positioning and welding, today’s robots are being fitted with milling, grinding and other heads so they can be used to deburr, grind, cut, trim, polish, linish, glue and more. These tasks require the robots to perform continuous precision motions, including area coverage patterns and removal of in-process material. It can be challenging to program this type of motion for robots using a manual approach or some of the existing software tools.

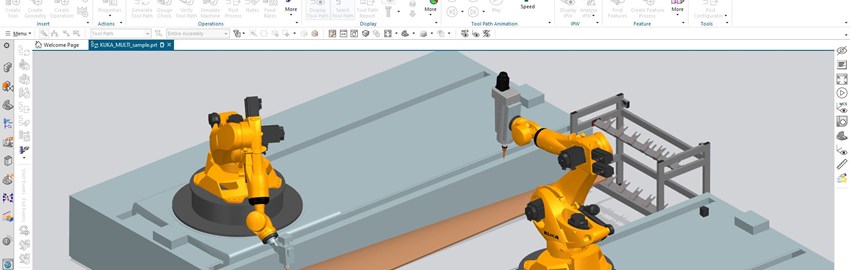

NX CAM Robotics software lets you design, simulate, validate, optimize and offline program your industrial robots for machining-type tasks. Using a specialised robotic programming software solution greatly increases the efficiency and quality of these high-precision, multiaxis robotic operations. The Siemens NX CAM software allows you to design, simulate and program your robot machines for machining-type tasks. Featuring the intuitive and widely-accepted NX software 3D environment, the software combines the simplicity of CNC programming with the power to accurately create, control and simulate complex robotic machining processes.

.